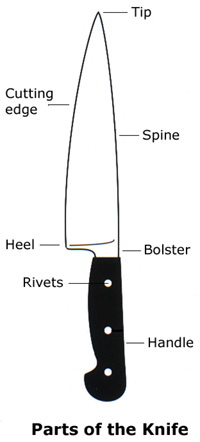

The Parts of a Knife

Blades

Blades

The most frequently used material for good quality blades is high-carbon stainless steel. Other materials, such as stainless steel and carbon steel are also available.

For many years, carbon steel was used to make most knife blades. Although carbon steel blades make a better edge than either regular or high-carbon stainless steel, they tend to lose their sharpness quickly. Also, carbon steel blades will discolor when in contact with high-acid foods, such as tomatoes or onions.

Carbon steel blades must be treated carefully to avoid discoloration, rusting and pitting; they should be washed and thoroughly dried between uses and before storage. The metal is brittle and can break easily under stress.

Stainless steel is much stronger than carbon steel and will not discolor or rust. It is very difficult to get a good edge on a stainless steel blade, although once an edge is established, it tends to last longer than that on a carbon steel blade.

High-carbon stainless steel is a relatively recent development that combines the advantages of carbon and stainless steel. The higher percentage of carbon allows the blade to take and keep a keener edge; the fact that it is stainless steel means that it will not discolor or rust readily.

The most desirable type of blade is "taper-ground". This means that the blade has been forged out of a single metal sheet and has been ground so that it tapers smoothly from the spine to the cutting edge, with no apparent beveling. Frequently used knives should be made with taper-ground blades.

Hollow-ground blades are made by combining two sheets of metal; the edges are then beveled or fluted. Although hollow-ground blades often have very sharp edges, the blade itself lacks the balance and longevity of a taper-ground blade. This type is often found on knives, such as slicers, that are used less frequently in the kitchen.

Tangs

The tang is a continuation of the blade and extends into the knife's handle. Knives used for heavy work, such as chef's knives or cleavers, should have a full tang; that is, the tang is as long as the entire handle. A partial tang does not run the length of the handle. Although blades with partial tangs are not as durable as those with full tangs, they are acceptable for less-used knives. Rat-tail tangs are much thinner than the spine of the blade and are encased in the handle (not visible at the top or bottom edges); these tangs tend not to hold up under extended use.

Handles

A preferred material for knife handles is rose-wood, because it is extremely hard and has no grain, which helps to prevent splitting and cracking. Impregnating wood with plastic protects the handle from damage caused by continued exposure to water and detergents. Some state codes require that plastic handles be used in butcher shops, because they are considered more sanitary than wood. Care must be taken to thoroughly remove grease, however, because it adheres more closely to plastic than it does to wood.

The handle should fit your hand comfortably. Manufacturers typically produce handles that fit a variety of hands. Spend some time holding the knife. A comfortable fit will improve the ease and speed with which you work. A poor fit can result in fatigue, or cramping. People with very small or very large hands should be sure that they are not straining their grip to hold the handle. Some knives are especially constructed to meet the needs of left-handed users.

Rivets

Metal fasteners called rivets are used to secure the tang to the handle. The rivets should be completely smooth and lie flush with the surface of the handle to prevent irritation to the hand and to avoid causing pockets where micro-organisms can accumulate.

Bolsters

In some knives there is a collar or shank, known as a bolster, at the point where the blades meets the handle. This is a sign of a well-made knife, one that will hold up for a long time. Some knives may have a collar that looks like a bolster but is actually a separate piece attached to the handle. These knives tend to come apart easily and should be avoided.

No comments:

Post a Comment